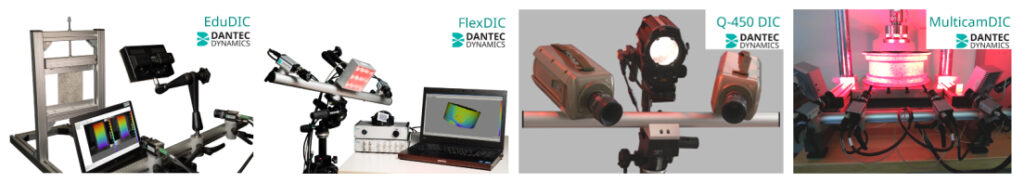

The Digital 3D Image Correlation System Q-400 or FlexDIC

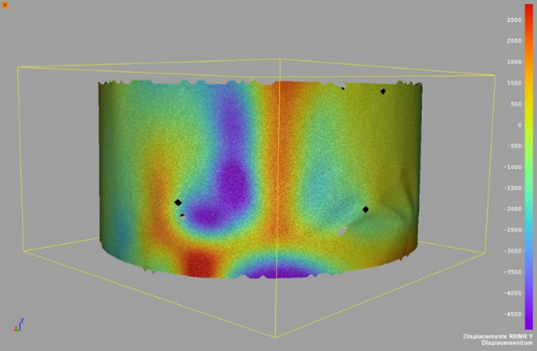

from Dantec Dynamics is an optical measuring device for true full-field, non-contact, three-dimensional measurement of shape, displacements and strains on components and structures made from almost any material.

The Q-400 system is used for determination of three-dimensional material properties in tensile, torsion, bending or combined tests. In addition, deformation and strain analysis can be applied to fatigue tests, fracture mechanics, FEA validation, and much more.

The flexible design of the Q-400 enables a wide range of applications from microscopic investigations on microelectronic or biomedical materials to large scale measurements

of aerospace, automotive, marine and railway components.

- Advanced materials (CFRP, wood, fiber injected PE, metal foam, rubber)

- Component testing (shape, displacements, strain)

- Material testing (Young’s Modulus, Poisson’s Ratio, Elasto-Plastic Behaviour)

- Fracture mechanics FEA validation

- High-Speed applications (dynamic measurements, transient events)

Take a closer look at the complete Digital Image Correlation (DIC) – Product Portfolio